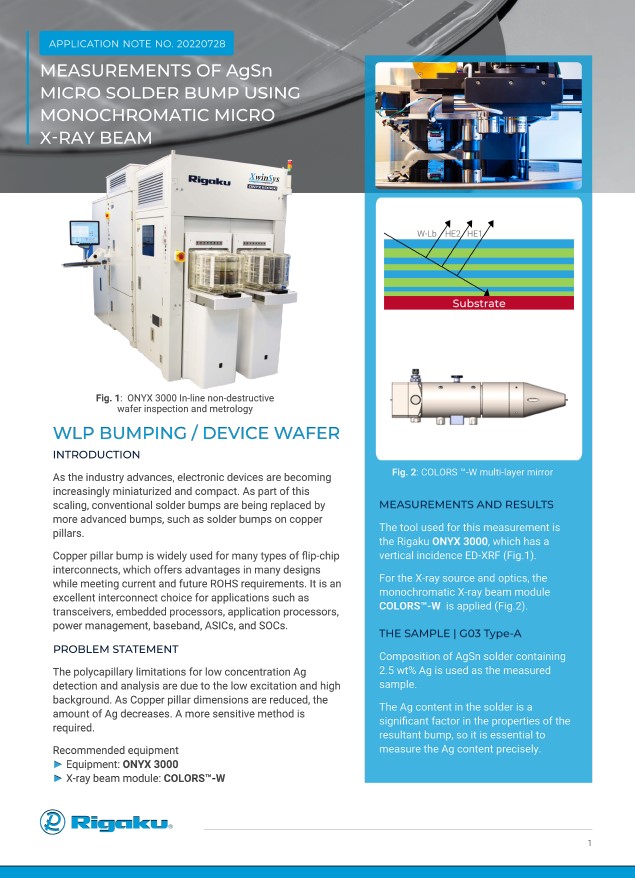

ONYX 3000

IN-LINE NON-DESTRUCTIVE WAFER INSPECTION AND METROLOGY

Hybrid configuration | automated x-ray analysis, 3D scanning, and 2D microscope for film thickness and composition measurements on blanket and patterned wafers

Is WAFER LEVEL PACKAGING an issue for your semiconductor manufacturing process?

EXPLORE ONYX 3000

< Click to play the video and view the ONYX 3000 in action.

Hybrid configuration | automated x-ray analysis, 3D scanning, and 2D microscope for film thickness and composition measurements on blanket and patterned wafers.

Got questions? Contact us for more information

TECHNICAL SPECIFICATIONS

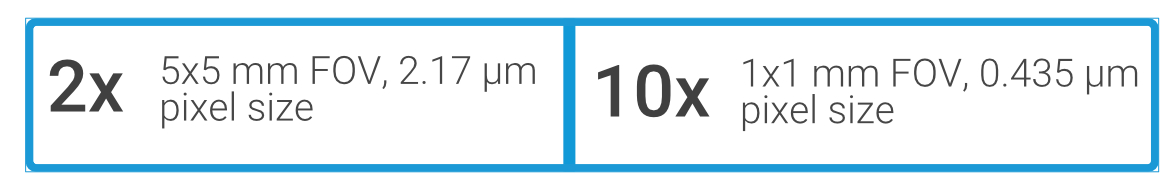

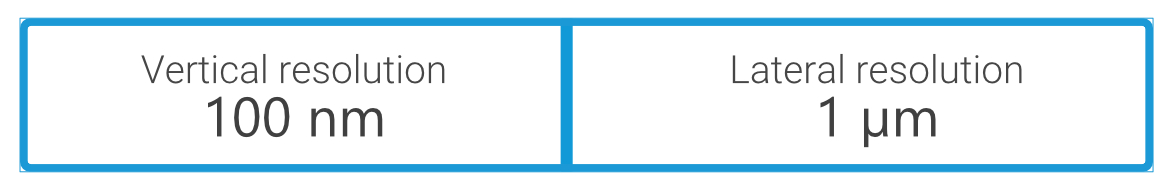

2D MICROSCOPE

2D MICROSCOPE MAGNIFICATION

3D SCANNER

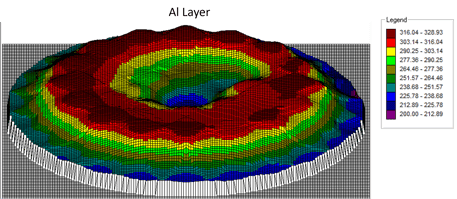

The optical feature with 2D microscope and 3D scanner enables defect detection, sizing, and characterization of BEOL structures through image analysis (of critical dimensions, height, roughness, etc. of metal stacks, solder bumps, pillars, etc.) complemented by elemental composition and thickness measurements by ED-XRF analysis.

Hybrid configuration | automated x-ray analysis, 3D scanning, and 2D microscope for film stack, bumps and composition measurements on blanket and patterned wafers

Layer-by-layer wafer inspection with qualitative and quantitative results

- XRF measures elemental composition and film thickness

- 2D Microscope used for pattern recognition, CD calculation.

- 3D Scanner height measurement, area scan, wafer surface roughness and bumps co-planarity

- Optimal configuration for bumps inspection

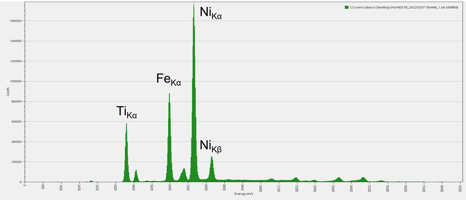

- Array of 4 silicon drift detectors (SDD) with large active area and 123 eV FWHM (@5.9 keV) resolution

- Measures light (low-energy) elements (carbon, oxygen, magnesium, aluminum, and phosphorous) using an optional helium atmosphere and special SDD detectors

- Monochromatic or polychromatic x-ray options

- Inspects micro-features through focused vertical X-ray beam (down to 10 µm diameter for polychromatic optics and 20 µm diameter for monochromatic optics)

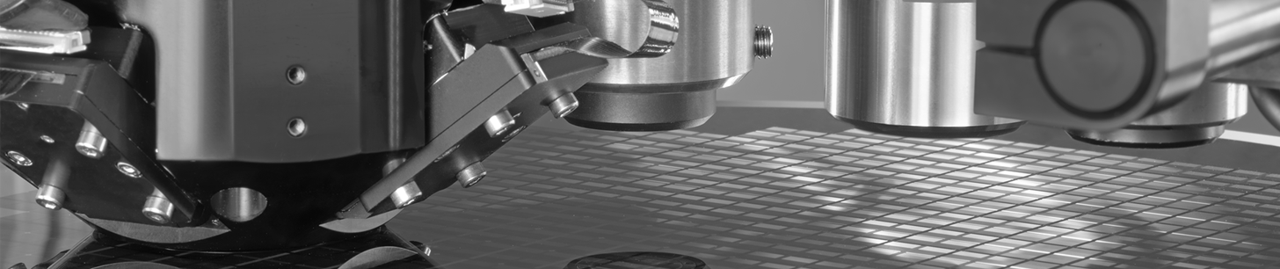

- Advanced motion platform for sub-micron accuracy

- Precise 3D geometrical inspection of features: micro-bumps, pillars, and pads

- Composition analysis associated with FinFET structures

- Fully automated calibration processes, ensuring long-term stability and consistency, and tube aging correction

- In line with SECS/GEM communication protocols

X-ray Optics Options

Polycapillary x-ray optics

Provide polychromatic and enhanced performance of XRF analysis to identify a wide range of elements efficientlyMonochromatic COLORS™-t x-ray optics

Enables measurements in low background spectrum enabling effective analysis of low signals.• High brightness excitation

• Small spots for a wide range of thin film applications.

• Ideal configuration for bumps and copper pillars inspection

SYSTEM PARAMETERS |

SPECIFICATIONS |

|

Metrology Type |

Micro-spot ED-XRF and optical inspection (2D-3D) |

|

Wafer Size |

Up to 300 mm |

|

Wafer Type |

Blanket and patterned wafers |

|

X/Y Stage Resolution |

< 1 µm (Stage resolution 0.1 µm) |

|

Sample Handling |

Magazine robot |

|

Automation |

Full wafer capability with single or dual automatic loader |

|

Navigation |

Precise stage complemented with an image recognition algorithm. Sub-micron fast navigation to single feature center. |

|

SW User Interface |

Auto calibration. Ease-of-use recipe creation and maintenance.Fundamental parameters optional. |

|

Micro XRF beam Orientation |

Vertical incidence micro-spot µXRF |

|

X-ray tube energy |

Up to 50 kV, 50 W |

|

Optics |

Polycapillary / COLORS™ |

|

Micro XRF beam Spot Size |

10-50 µm spot sizes adjustable |

|

Detector Type |

Silicon drift detector (SDD) optional: light element detector (C,N,O,F.S) |

|

Detector Resolution |

123 ± 5 eV with a large solid angle |

|

DPP | Digital Pulse Processor |

High efficiency of more than 1 million photons/sec. |

APPLICATIONS

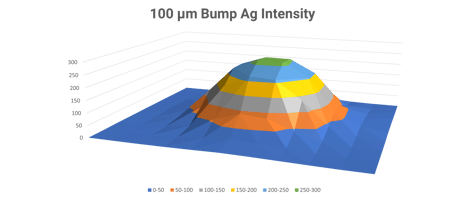

SINGLE-BUMP METROLOGY

Measure and monitor Ag%, Sn%, Ni layers, Cu thickness, and total bump height:- Measure single-solder bumps as small as 10 μm diameter

- Inspect a range of parameters: across the wafer, wafer-to-wafer, and lot-to-lot

- Measure CD and a total height of single bumps using a 2D microscope, 3D scanner, and built-in sensors

THIN FILMS Measuring and monitoring

Measure and monitor thickness and composition of precious metal thin films:

- Analyze ultra-thin films of any type of element, regardless of their physical properties

UBM/RDL

Conduct metallurgical inspections of under bump metallization (UBM) and redistribution layers (RDL):- Analyze multi-stack structures and thick monolayers, for layer thickness and composition

- Distinguish separate layers simultaneously

ALLOY COMPOSITIONS

Measure and monitor metals and alloy composition:

- Analyze metal elements (Ga, P, Co, Ni, Fe, Pt, Cr, Zn, and Mn)

- Identify alloys (NiFe, CoNi, NiP, NiPt, and CrMn)

ONYX 3000 RESOURCES

App. Note 20101831 ULTRATHIN Ru THICKNESS FEOL WAFER PROCESSING / BLANKET WAFER

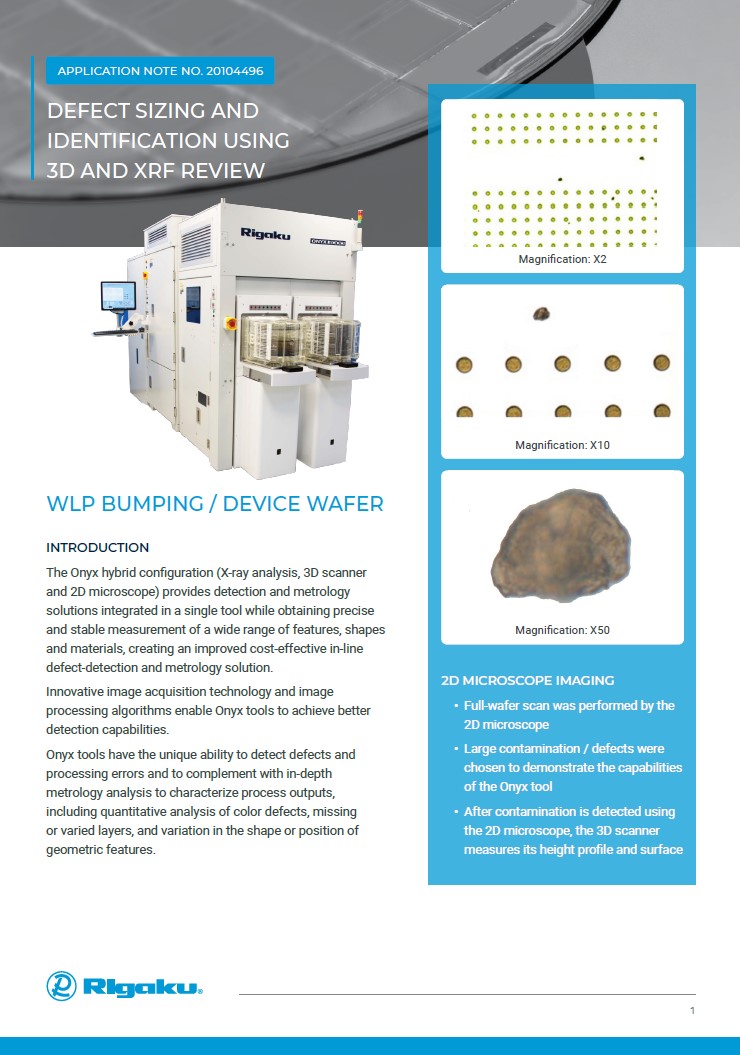

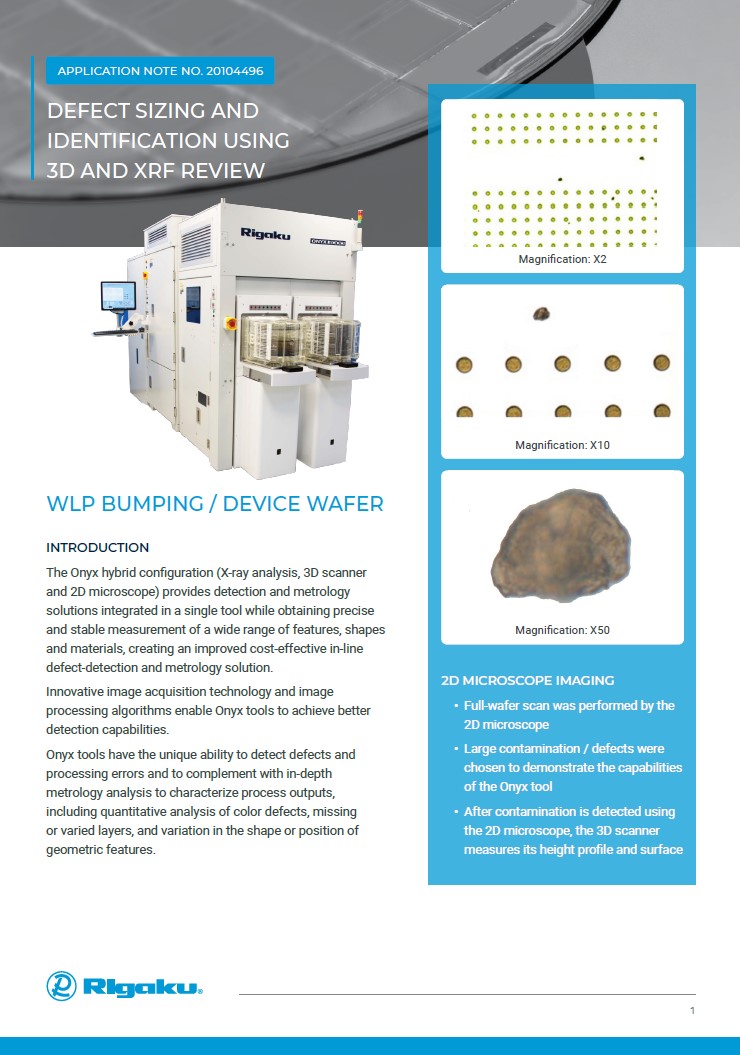

App. Note 20104496 DEFECT SIZING AND IDENTIFICATION USING 3D AND XRF REVIEW WLP BUMPING / DEVICE WAFER

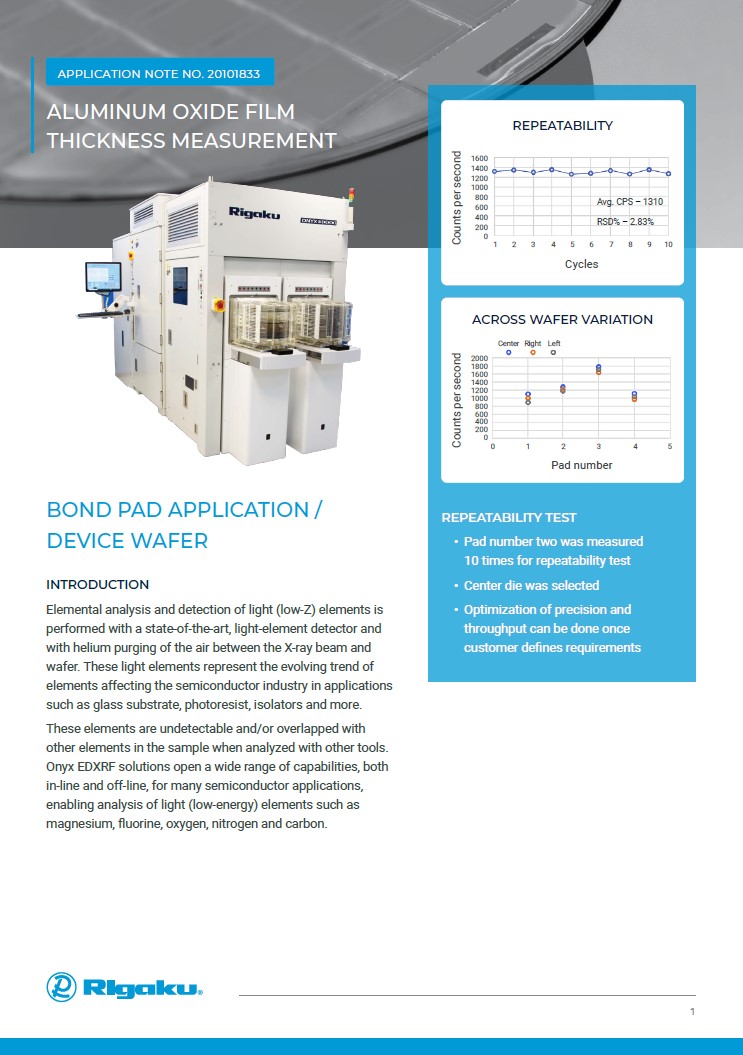

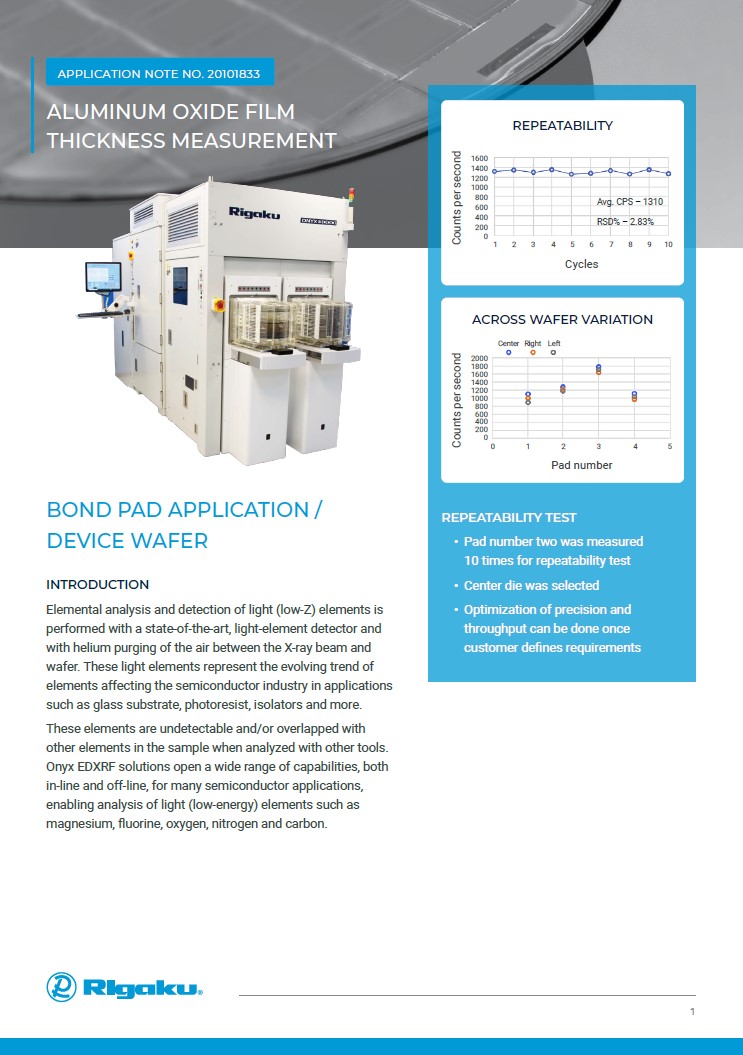

App. Note 20101833 ALUMINUM O XIDE FILM THICKNESS MEASUREMENT

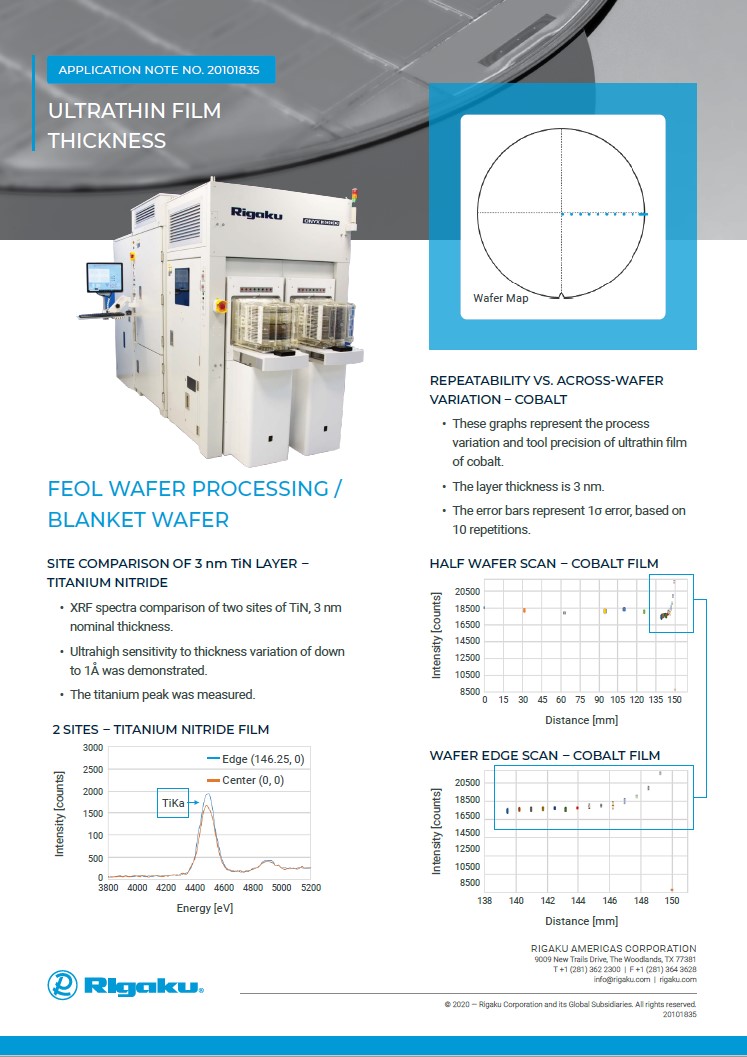

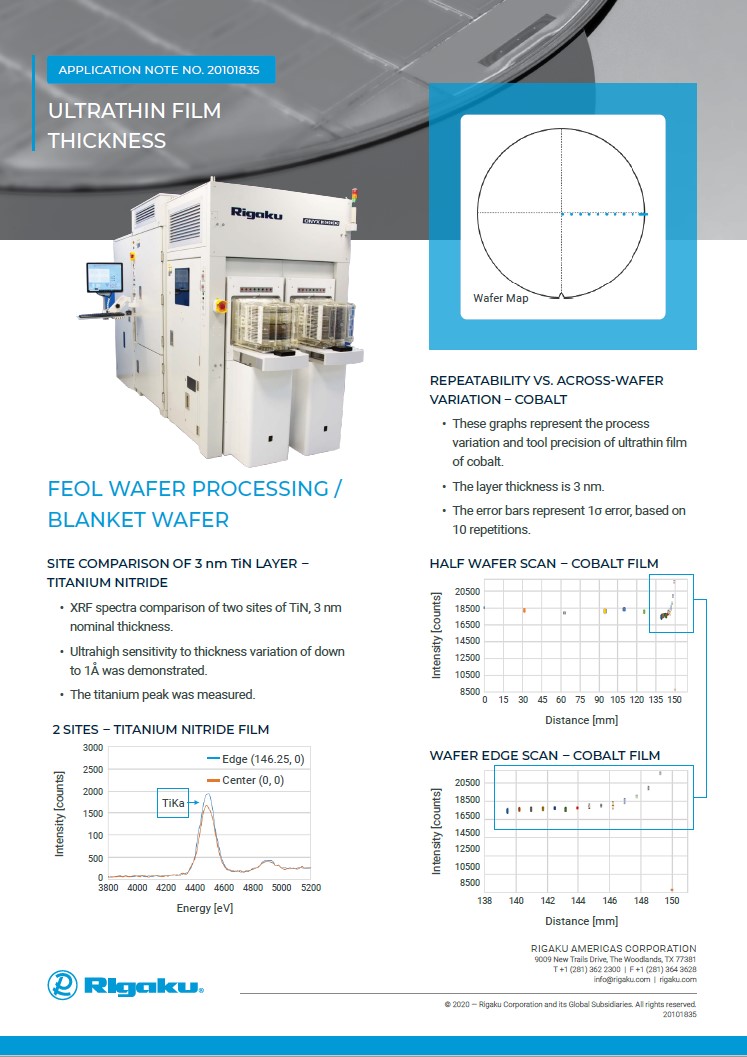

App. Note 20101835 ULTRATHIN FILM THICKNESS

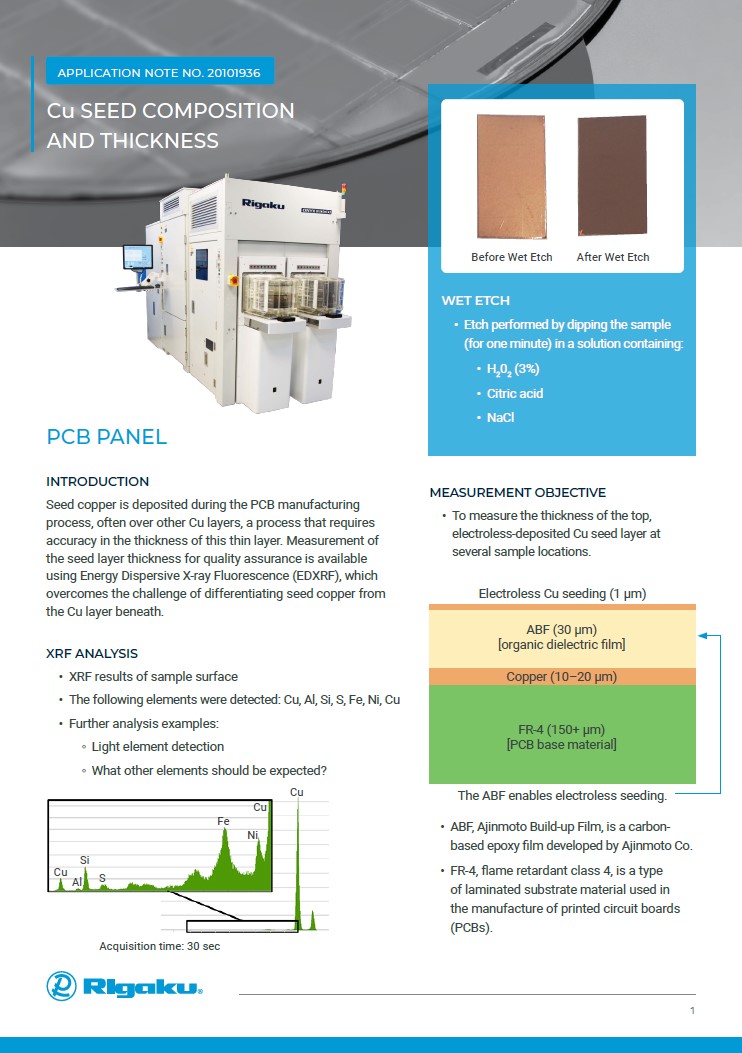

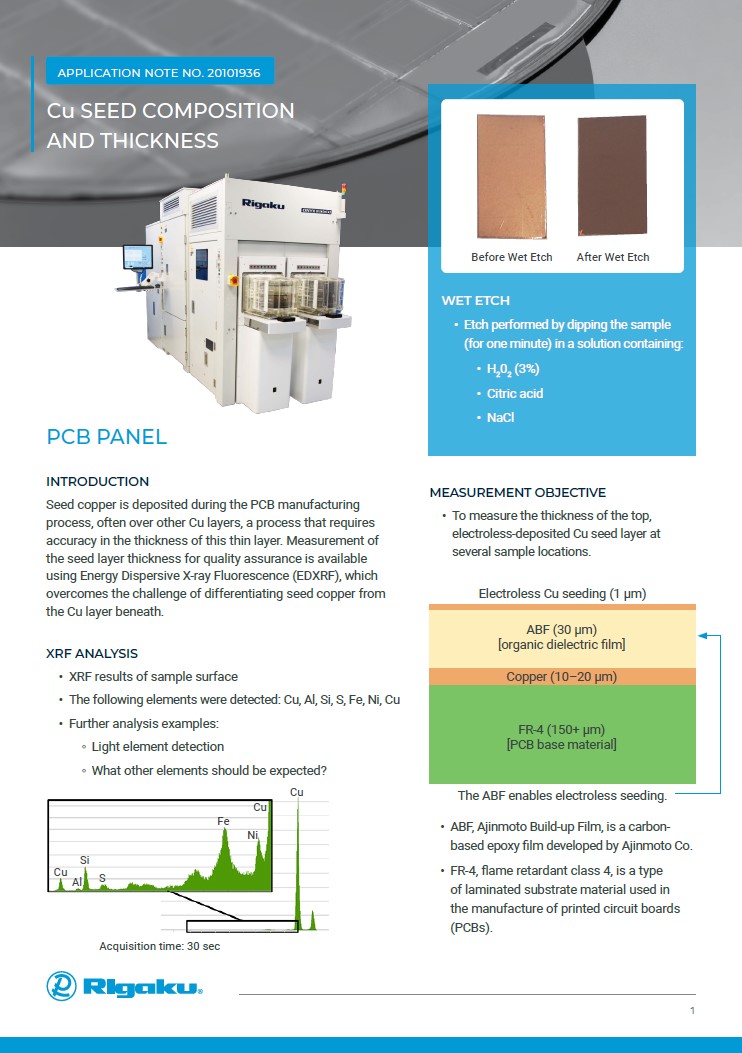

App. Note 20101936 Cu SEED COMPOSITION AND THICKNESS

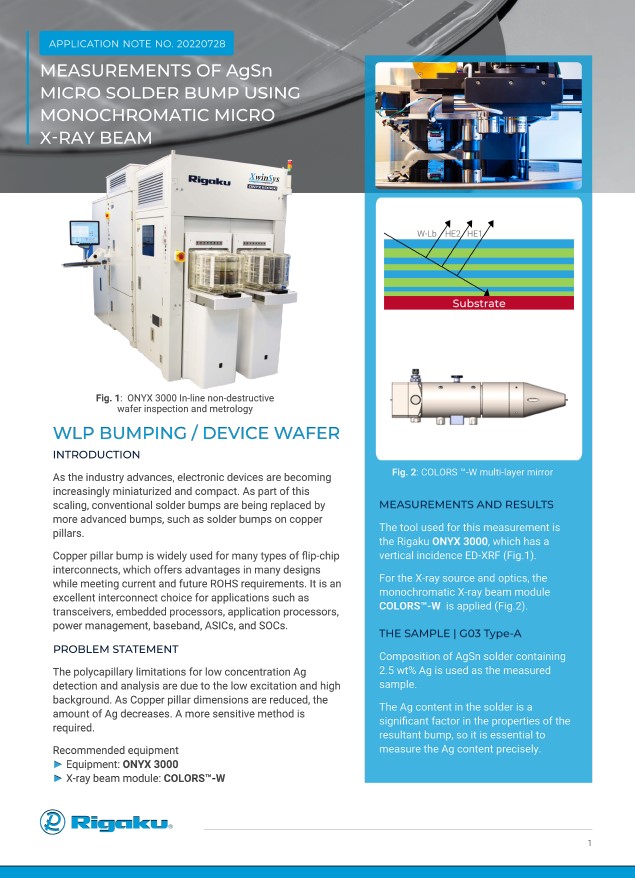

App. Note 20220728 Measurements of AgSn MICRO SOLDER BUMP Using Monochromatic MICRO X-RAY BEAM

App. Note 20101831 ULTRATHIN Ru THICKNESS FEOL WAFER PROCESSING / BLANKET WAFER

App. Note 20104496 DEFECT SIZING AND IDENTIFICATION USING 3D AND XRF REVIEW WLP BUMPING / DEVICE WAFER

App. Note 20101833 ALUMINUM O XIDE FILM THICKNESS MEASUREMENT

App. Note 20101835 ULTRATHIN FILM THICKNESS

App. Note 20101936 Cu SEED COMPOSITION AND THICKNESS

App. Note 20220728 Measurements of AgSn MICRO SOLDER BUMP Using Monochromatic MICRO X-RAY BEAM

TRUSTED PARTNER

Pharmaceuticals have the power to change the world for the better, but before they can ever do that, they need to be proven safe and trustworthy. Here at Rigaku, we strive to make this a reality as the leading global scientific analytical instrumentation company specializing in X-ray and thermal analysis, and Raman spectroscopy.

CORPORATE MISSION

To contribute to the enhancement of humanity through scientific and technological development.

CORPORATE MOTTO

Value our customers, value our people, and value our technology